By Chris Bryant

Photographs by Zach Riggins

The odds of predicting when the United States would pass major climate and energy legislation appear, like the weather itself, to be somewhat cyclical.

At various times since the Kyoto Treaty was first adopted almost 14 years ago, it has appeared any such legislation was either imminent, years away, or most any point in between.

In July 2010, some speculated that the Senate’s then inability to bring legislation on a greenhouse gas emission trading system to a vote was a death knell. Less than one month later, however, the White House’s top energy adviser suggested that a cap-and-trade bill might be passed following November’s mid-term elections.

Despite the ever-swinging pendulum representing momentum, or lack thereof, behind such legislation, Dr. Peter Clark, a University of Alabama petroleum/chemical engineer, says the question, to him, has always been a matter of when not if.

“As much as people would like to pretend it is not going to happen, there is going to be a tremendous amount of pressure from the rest of the world to do this,” Clark says. “Clearly, it’s better to get ready to do it at this time than to wait and to later be in a panic.”

A trio of University of Alabama researchers, in collaboration with various governmental and commercial entities, is exploring one avenue, carbon dioxide storage, which could prove helpful to industry in getting ready for any future reduction requirements in greenhouse gas emissions.

Three separate research projects, funded with nearly $13 million, involve UA scientists seeking to better gauge the feasibility of pumping carbon dioxide into the ground for long-term storage as an alternative to releasing the greenhouse gas into the atmosphere.

PAY NOW OR PAY LATER

“Under cap and trade, utility companies are either going to have to pay for their CO2 emissions or they are going to have to sequester them in some fashion,” Clark says. “They can trade carbon credits if they want, but to generate their carbon credits they have to save either at the generation of CO2 or they have to inject, or otherwise dispose, the CO2 some place. For big coal-fired electricity plants, the cost of buying enough credits to continue to put CO2 into the atmosphere would be high, so they see sequestration as one way to potentially solve the problem.”

In one project, Clark leads a team of scientists, including UA colleagues Drs. Eric Carlson and Andrew Goodliffe, in studying whether a saline reservoir, more than one-half mile below the surface and stretching across a large swath of the state, is a good option for storing carbon dioxide.

It has potential. And, it is not alone.

“Alabama is probably one of the best places to do carbon sequestration because we’ve got great reservoirs,” says Goodliffe, a UA geophysicist. “What we have in the Black Warrior River basin are big power stations and some beautiful geology beneath them. And that geology is potentially an ideal reservoir for carbon sequestration storage.”

While the term “saline reservoir” might suggests to the lay person a cavernous opening underneath the surface, with a wide saltwater stream flowing through it, that’s not the case, the researchers say.

Instead, such reservoirs typically consist of a host of tiny spaces within underground rocks.

“In a good saline reservoir, you might have 30 percent porosity,” Goodliffe says, “which means that 30 percent of that rock is holes that you can potentially put water, oil, gas, whatever, into.”

LOCATION, LOCATION, LOCATION

However, thinking this means there’s not much available space in which to potentially store carbon dioxide is also incorrect.

“The Tuscaloosa trend that starts just south of the mid-part of Alabama and runs clear off shore is just mammoth,” says Clark. “Just the onshore part is 69 gigatons of carbon dioxide storage.”

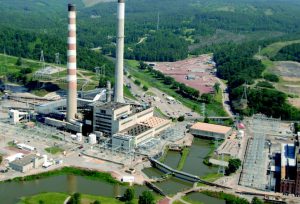

Alabama Power and Southern Co. are corporate sponsors of the Department of Energy-funded project, and the research site is near Alabama Power’s William Crawford Gorgas Plant in Walker County. In fact, the real estate axiom, “location, location, location,” identifying the three most important attributes of property, come to mind for this project, as well. By investigating the geology near existing power plants, costs associated with later transporting carbon dioxide from the plants are greatly reduced.

Fewer than five miles from Gorgas is Alabama Power’s Miller plant. And it’s Miller’s emissions, not Gorgas’, that are the potential target for this carbon storage project. The geology underneath Miller is not as well suited for carbon storage, Clark says, but its close proximity to Gorgas lessens any future costs related to transporting carbon dioxide.

Carbon dioxide, a major greenhouse gas, contributes, the majority of scientists say, to climate change. Its atmospheric concentration levels have increased, at least in part, because of the consumption of fossil fuels. In theory, this new approach to carbon storage would work by removing carbon dioxide from flue gas emissions, compressing it into a liquid and pumping it into the underground saline reservoirs via wells.

Capturing the carbon dioxide is a significant hurdle – one being tackled by other researchers – while this UA-led team is focusing on assessing the underground storage capacity and its capability to keep the CO2 safely in place, long-term.

Over the next three years, the team will create and analyze – using seismic reflection technology – a detailed image of the geology below the surface, build geological and reservoir computer models to predict potential outcomes of injecting and storing the carbon, and drill and test an 8,000-foot well by which the carbon dioxide could be injected. However, at this stage of the project, it will be fresh water, not carbon dioxide, that will be injected.

“We will inject a small volume of fluid into the hole – and there will be down-hole pressure sensors – and we will do so at a number of different pressure and flow rates,” Clark says. By analyzing the data from the tests, researchers get a better idea of the site’s potential permeability and injectivity.

UNDERGROUND ACOUSTICS

Using core drills, the researchers will remove large cylindrical sections of rock, three to four inches in diameter and as much as 30-feet-long. Repeating these steps, layer after layer, provides the researchers enormous sections of rock for laboratory analysis.

But, alone, these steps don’t necessarily give an accurate indication of the characteristics of underground areas surrounding the drill sites.

Researchers also use a large vehicle, known as vibroseis truck, to send acoustic signals, via vibrations, deep underground. Those signals reflect off the various rock layers across a five-mile line and to a depth of more than 10,000 feet. The signals are received back at the surface by sensors known as geophones.

“By analyzing all those vibrations, we actually build up a two dimensional image of the subsurface,” says Goodliffe. “The combination of those two, the seismic data and the well, allows us to take that well data and say, ‘we know the geology at the one location, and, using the seismic data, we can extrapolate that out. I can start to build up a very detailed image of what the rocks are within the basin.”

Another key step involves placing sensors in the bore hole and measuring how long it takes acoustic pulses sent down the hole to reflect back to the geophone sensors at the surface. Goodliffe explains.

“When we drill our well, that’s in depth. We’ve got to come up with a way to correlate time to depth. That acoustic signal travels down the bore hole, and we know how long it takes to reach these acoustic sensors in the subsurface, and we know the depth of those sensors. That gives us a direct tie between time and depth and allows us to take that time section and correlate it directly to the bore hole.”

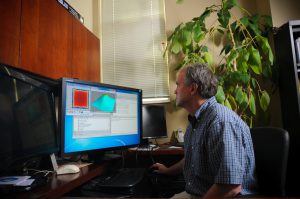

Carlson, a UA petroleum engineer and computer modeling expert, will take the seismic data, along with reams of additional data provided by other research partners, and develop multiple mathematic models.

“Once we have the mathematical models, we will take and translate those in a way that our computers will be able to simulate, over many, many years, what happens as we inject CO2 into the formation,” Carlson says.

“Does it react with something and precipitate out? Does it continue to move and move and move? Do we inject it, and … it goes up fractures and faults?” Or, in a more promising scenario, do the simulations indicate that 99 percent of the carbon will stay in place for more than 1,000 years – a desired outcome.

SIMULATING POSSIBILITIES

To visualize the computer simulation effort, Carlson suggests thinking of a room – representative of the reservoir – divided into tiny compartments, or cells, all stacked atop and beside one another.

“We assume, based on certain mathematical descriptions, that we will allow things to flow from one cell to another. Eventually, something we inject down here,” Carlson says, while pointing to the lower corner of his office, “will eventually possibly make it over here to some other corner.

“For each of these cells, there will be physical properties that we will use to describe that,” Carlson says.

“Things like CO2 concentrations, pressures, temperatures, stresses, amount of water – there are many things we will track inside each of these cells.

“We will not be doing a single simulation,” Carlson says. “We will be doing what we call realizations. We will generate – using some random, intelligently constrained, but otherwise random – assignment of certain characteristics. We might run tens or hundreds or thousands of these simulations just to get a picture.”

Carlson says the first step, for him, is to develop the computer infrastructure and software capable of handling such large-scale simulation. Software and a single PC used in the project must have the capability, initially, of simulating 50 million cells.

“It’s very plausible that at the end of three years, I will be up to 500 million cells on maybe five machines.”

WILL IT STAY PUT?

The modeling’s end result will attempt, Carlson says, to answer questions such as how much CO2 can be injected into the reservoir, what happens to it once it goes in, how quickly it can be injected and where it can be injected. “And, probably the most important question, from the standpoint of carbon storage, does it stay in the ground?”

In a second Department of Energy-funded project, Clark and Carlson are joining with researchers from the Geological Survey of Alabama and elsewhere to study not only storing carbon dioxide at another site, but, simultaneously, to also use the CO2 injection as a means of increasing the amount of natural gas that can be recovered from various coalbed methane sites in Alabama.

“This will help pay for the cost of capturing and injecting the carbon dioxide,” Clark says. At a Tuscaloosa County test site, chosen for its characteristics which are representative of others in the Black Warrior River basin, the researchers began injecting CO2 in June. Over a 60-day period, the researchers injected 240 tons of CO2, while monitoring factors such as reservoir pressure, gas composition, water quality and the CO2 plume, itself. When CO2 is injected into a coal seam, it displaces the methane gas. The injected CO2 absorbs onto the coal where it is stored.

Coal sites within the 23,000-square-mile river basin have the potential to store between 1.1 and 2.3 gigatons of CO2, the researchers say. This is roughly the same amount of CO2 produced by Alabama’s coal-fired power plants in two decades. Researchers estimate that another 1.5 trillion cubic feet of natural gas that might otherwise go unclaimed could be generated through the use of CO2 injections. In addition to UA, partners include Southern Company, El Paso Exploration and Production and the Geological Survey of Alabama.

In a third project at Citronelle Oil Field in Alabama’s Mobile County, researchers are, in similar fashion, hoping to force additional oil from the field by injecting CO2 into the site and pushing the oil forward. Such enhanced oil recovery efforts have “almost completely revived” the oil industry in West Texas, Clark says.

STUDENTS TO BENEFIT

In addition to the potential environmental and industrial benefits that would result from the carbon storage projects, Goodliffe says the benefits to those University of Alabama students involved in the research will be significant.

“In five to 10 years, carbon sequestration is going to be its own industry,” Goodliffe says. “I’m really excited for our students because they have the chance to get in on the ground floor. There are very few people who are actually going to be trained directly in this. They will be ready to hit the ground running, and my goal is that they will be running these companies in 10 years time.”

And don’t think Clark hasn’t heard the arguments that the impact of CO2 emissions into the atmosphere is overblown and unrelated to higher temperatures.

“Clearly, coal and oil are generated from materials, mostly plants, that were alive at one time,” Clark says. “So, there’s the argument that CO2 was taken out of the atmosphere when the plants were buried and all you are doing is putting back the CO2 that was there naturally. But, the fact remains that when you generate huge amounts of CO2 through burning, you upset the natural processes of generation and use of CO2. You’ve put in a source of CO2 that isn’t part of the natural system.”

“Whether you believe in global warming or not, the things we are doing it to combat it – developing higher efficiency techniques – perhaps capturing CO2 – are things we should be doing anyway. We should be looking for more efficient cars and more efficient ways to run our household. We can’t go and make plastic forever without recycling some of it.

“You can make a good case for global warming, and you could make a good case that this is sort of a natural heating that is occurring because of the cycles that we go through. We’ve gone through high-temperature cycles and low temperature cycles. But, you can’t argue that the CO2 concentration is going up in the atmosphere. There’s no doubt about that.”

In The University of Alabama-led project at the Alabama Power site, researchers from UA’s colleges of Engineering and Arts and Sciences are collaborating with the Alabama Geological Survey, Rice University and Schlumberger. In the Black Warrior CO2 Storage Project, UA researchers are partnering with Southern Company, El Paso Exploration and Production, the Geological Survey of Alabama and the Electric Power Research Institute, known as EPRI. In the Citronelle Oil Field Project, led by the University of Alabama at Birmingham, UA researchers collaborate with Denbury Resources Inc., Southern Company and Alabama A&M.