Engineering researchers at The University of Alabama will test a blend of a new bio-based fuel and diesel fuel as part of a project to reduce soot and greenhouse gas emissions and yield cleaner engine operation in cold-weather conditions.

The diesel fuel will be blended with the chemical butyl acetate, or BA, produced in a novel way by researchers at Auburn University.

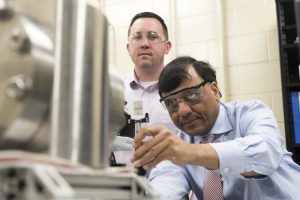

“We are providing support from the end user side,” said Dr. Ajay K. Agrawal, UA professor and the Robert F. Barfield Endowed Chair in Mechanical Engineering. “We will find out how this fuel mix improves engine emissions and efficiency both inside the engine cylinder and in an actual engine during a typical drive cycle.”

The work is part of a $2 million U.S. Department of Energy project led by Auburn that promises to improve fuel emissions and efficiency. Other collaborators are Cornell University, Virginia Tech University and corporate partners EcoEngineers and Microvi Biotech Inc.

The project is one of 42 totaling $80 million awarded by the DOE to support advanced vehicles technologies research.

Auburn researchers are developing an integrated bioprocess for efficient production of BA, an organic compound that occurs naturally in various fruits and can be used as a flavoring in the food industry and a feedstock in various other industries. BA can be produced chemically.

However, traditional petrochemical-based BA production is energy consuming and not environmentally friendly, said Dr. Yi Wang, principal investigator for the project and assistant professor in the department of biosystems engineering in Auburn’s College of Agriculture.

Wang and the Auburn team developed a customized CRISPR-Cas9 genome engineering system that has resulted in an engineered strain with the highest BA production ever reported in a microbial host. The process uses a strain of Clostridium—a group of bacteria that thrive in the absence of oxygen—known for its ability to produce butanol.

“In this project, we will further enhance BA production through systematic genome engineering,” Wang said. “CRISPR technology has been used by many different labs, but we are one of the pioneering labs who have developed the customized CRISPR system that can be applied to the solventogenic clostridial strains, which are notoriously difficult to manipulate genetically.”

Using existing capabilities, the UA researchers will help understand how the fuel mix ignites and reacts in diesel engines used in highway trucks. Different mixes of the fuel – some with more BA than others – will be investigated using a unique spray diagnostic apparatus developed at UA and in UA’s heavy-duty diesel engine test platform, one of the few engine test cell facilities in the country.

“Our engine facilities and capabilities complement well with Auburn’s ability to produce the fuel,” said Dr. Joshua A. Bittle, UA assistant professor of mechanical engineering.

In the first part of the project, UA researchers will use a Constant Pressure Flow Vessel, or flow rig, to simulate fuel-air mixing processes inside a diesel engine and monitor it with advanced optical diagnostic techniques integrated with multiple high-speed camera systems. The flow rig simulates the temperatures and pressures inside an engine just before fuel injection. Cameras record the event as the fuel is injected, ignites and combusts.

The experimental results will be provided to Auburn researchers to refine the fuel production. Then, the UA researchers will test the improved fuel in a production heavy-duty diesel engine in the UA College of Engineering’s Engines and Combustion Laboratory. Engine tests will be performed over the EPA defined drive-cycle used to certify engine emissions compliance. These tests will provide a realistic estimation of the benefits of BA-diesel blends on engine performance.

Before a new process such as this can be up-scaled for commercialization, a techno-economic analysis is warranted. Virginia Tech’s role in the project is to conduct this analysis to evaluate the economic practicality of the biofuel being produced, said Dr. Haibo Huang, an assistant professor in the Department of Food Science and Technology.

Researchers at Cornell will examine more fundamental aspects of blending BA with diesel fuel in the form of droplets that represent the sub-grid element of a spray used for fuel injection into combustion engines, said Dr. Thomas Avedisian, professor with the Sibley School of Mechanical and Aerospace Engineering at Cornell University.

The bioprocess development for high-efficiency BA production in this project is based on an innovative technology called MicroNiche Engineering developed by Microvi Biotech.

Another corporate partner in the research project is EcoEngineers, a renewable energy consulting firm that will perform a lifecycle emissions analysis of BA as a bioblendstock for diesel fuel. .