TUSCALOOSA, Ala. — Tasked with reducing the weight of a Chevrolet Camaro transforming into a hybrid electric vehicle, engineering students at The University of Alabama successfully fabricated a lighter hood, proving a cutting-edge material can work on a consumer car.

The new hood is made of a mixture of graphene and carbon fiber, while the original hood is aluminum, as are nearly all exterior parts on consumer passenger vehicles.

It is the first hood with graphene fused into the material, likely giving it some flexibility lacking in a hood made of only carbon fiber.

It is also half the weight of the original hood, a crucial adjustment as a larger team of students work to turn the Camaro into a plug-in hybrid as part of a national contest called EcoCAR 3.

Graphene is an atomically thin layer of the mineral graphite that is stronger and lighter than any metal or carbon-based material.

“The idea of the carbon fiber with graphene was to lightweight the hood so that you have weight reduction while still maintaining the physical strength and performance of the hood,” said Zach Reasoner, a senior from Greenwood Village, Colorado, who is studying mechanical engineering and who worked on the project.

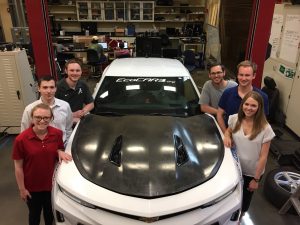

Six students designed and tested the hood as a senior project over the past two semesters.

The hood will be used by UA’s EcoCAR 3 team competing against 15 other North American universities to design and construct a car that uses less energy and emits less pollution without sacrificing performance, safety or consumer appeal. General Motors Co. and the U.S. Department of Energy sponsor the four-year engineering competition.

The national EcoCAR 3 contest is a chance at industry visibility for graphene, said Dr. Rachel Frazier, assistant director of the Alabama Innovation and Mentoring of Entrepreneurs center at UA.

“This is a prototype that shows graphene can be used in a consumer car, and the Camaro is a pretty sexy car to show proof of concept,” Frazier said.

Frazier invented methods to make graphene and graphene-based plastics, spinning off a company in the Bama Technology Incubator, Graphenics, to help automotive companies incorporate graphene into products. Leaders with the EcoCAR 3 team approached her to see if graphene could shave weight off the Camaro, she said.

Megan Hathcock, a senior in mechanical engineering from Huntsville, is technical lead for the EcoCAR 3 mechanical engineering team, and she served as lead for the group of seniors who took on the project to lessen the weight of the hood.

The students on the EcoCAR 3 team added a lot of weight while focusing on getting the hybrid engine and battery system to work, but they needed to lower the weight to improve efficiency, she said.

After months of computer modeling and material tests, the engineering seniors settled on a carbon fiber hood with less than one percent of graphene. They made resin of the material that they vacuum infused into a mold of the hood, later drilling and finishing the hood to fit onto the Camaro.

The new hood weighs 11.1 pounds, less than the 22.1 pounds of the original hood, meeting the goal to cut the weight of the hood in half. It also fits flush with the rest of the car.

They made three hoods, but needed to test it to be sure the hinges would stay intact and that the hood would not shatter or penetrate the windshield during a crash, which is a federal auto safety standard.

“We had to make sure our hood met the Federal Motor Vehicle Safety Standards so that GM would approve it and use it in the EcoCAR competition,” Hathcock said.

Using a testing apparatus they constructed, the students mimicked a 30-mph head-on collision with weights. The hood buckled under the force without splitting, and, in fact, returned to its original form after crash, demonstrating flexibility.

“It’s a very interesting result because you would not expect carbon fiber to return to its original shape,” said Ryan Scalf, a senior in mechanical engineering from Glendale, Arizona.

While graphene is superior to parts made of aluminum and carbon fiber, manufacturing costs prohibit widespread adoption, Frazier said.

The engineering students beat the project constraint of keeping the cost of their hood within five times the cost of the original hood despite not having advantages of a large-scale factory. In fact, the student team estimates the new hood costs less than twice that of the original aluminum hood.

The students and Frazier said graphene is following the path of other advances in vehicles through use in motorsports and niche markets before the cost becomes feasible on passenger vehicles.

Also, Frazier said stricter emission standards will be a factor in adoption as lowering weight is a way to increase a vehicle’s miles per gallon.

“After working with this team for two semesters, they have demonstrated perseverance, outstanding problem solving skills and a dedication to innovation and product delivery that exemplifies qualities of UA engineering graduates,” Frazier said.

Besides successfully making a hood, the students said they learned a lot from the project, which drew from several fields including chemistry, mechanics, material science, engineering and manufacturing.

“As a whole, we learned a lot about the engineering design process, and overcoming obstacles with solutions we faced along the way is going to be very valuable in our careers,” Reasoner said.

Along with Hathcock, Scalf and Reasoner, the team included mechanical engineering seniors Nicholas Davies, from Birmingham; Assunta De Pau, from Palatine, Illinois; and Jacob Horton, from Joshua, Texas.

The team’s faculty adviser is Dr. Brian Jordon, associate professor of mechanical engineering.

Contact

Adam Jones, UA Media Relations, 205/348-4328, adam.jones@ua.edu