TUSCALOOSA, Ala. – A team from The University of Alabama and Shelton State Community College will defend its title at one NASA robotics contest before tackling another contest.

After finding success with the NASA Robotic Mining Competition, members of Alabama Astrobotics are turning their attention to a different NASA challenge, the Sample Return Robot Challenge. Both contests require the students to build robots capable of collecting samples from the ground. Team members hope the overlap between the contests improves both robots they built over the past year.

“There were members of the team who wanted a new problem to solve, so tackling Sample Return has given us that opportunity,” said Caleb Leslie, a graduate student in electrical and computer engineering who serves as team lead for Alabama Astrobotics.

But before the team competes in the first leg of the NASA Sample Return Challenge in June, it travels to Kennedy Space Center in Florida for NASA’s space-mining contest, which begins Monday, May 16.

In the six years since NASA began hosting its Robotics Mining Competition, Alabama Astrobotics has emerged as the competition’s most successful team, winning in 2012 and 2015. It is the only team in the competition’s history to finish in first place more than once. The team also placed second in 2014 and third in 2013.

“Our successes are the result of having talented, dedicated students who recognize the value of hard work and who are not afraid to put in the hours necessary to be successful, “said Dr. Kenneth Ricks, UA associate professor of electrical and computer engineering and team adviser. “Our students understand the commitment required, and they have demonstrated they are willing to do the work.”

The technology concepts developed by the collegiate teams for this competition could be used to mine resources on asteroids as well as Mars, according to NASA. The agency will benefit directly from the competition by encouraging the development of innovative excavation concepts from universities. The process may result in clever ideas and solutions that could be applied to an actual excavation device or payload.

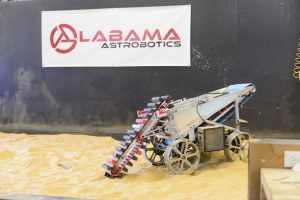

As part of the competition, students are required to design a robot capable of navigating through and excavating 10 kilograms of simulated Martian regolith, a layer of loose material that covers a solid rock.

A year ago, the team’s robot completed a dig in the contest without students navigating or operating it. The robot was the first in the contest’s history to complete a run with complicated autonomous programming that could be used by an actual NASA robot on another planet or asteroid, Ricks said.

Like every year, the team designed and built a new robot. For this competition, however, the students kept the design from last year, improving some of its mining capabilities, making it lighter and upgrading its ability to operate on its own, Leslie said.

“We’ve tried different things in years past, but we’ve settled on this design because it’s a very difficult design to beat because it’s so efficient,” he said. “The big focus has been autonomy and controls, so we’re trying to control it in a much smarter way.”

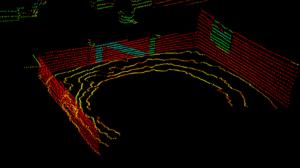

Improvements include changes to the robot’s programming, or algorithms, that control autonomy, and upgrading the sensors that scan the competition arena that allow the robot essentially to see its surroundings and navigate around them, Leslie said.

Last year, Alabama Astrobotics was the only team to use lidar sensors on the robot. The sensors use lasers to measure distance and determine an object’s position, a sort of radar that uses light instead of sound. This year, the team is using a lidar sensor that can scan in 3-D, shooting out 16 laser beams instead of the one beam used last year, Leslie said.

The team will be judged on an oral presentation; a written systems engineering paper; project outreach in promoting science, technology, engineering and math disciplines; team spirit; and the mining category.

Within the mining category, the robot is judged on its overall weight, the amount of regolith collected, the amount of bandwidth required in communicating with the robot, the degree of autonomy demonstrated by the robot, and the degree of dust protection demonstrated by the robot.

With the NASA Robotic Mining Competition, autonomous robots help score points and challenge students, but the robots can be driven and operated by students by remote control. For the Sample Return Challenge, robots are required to operate on their own.

Also, a contest run is two hours, not two runs of 10 minutes as in the space-mining contest. In the new contest for UA, NASA tasks teams to create a robot with autonomous capability to locate and retrieve specific sample types from locations over a wide and varied terrain and return those samples to a designated zone in a specified amount of time with limited mapping data.

Leslie said the contest takes place over an area roughly the size of UA’s Quad, and the samples the robots have to collect range from colored rocks to metallic objects.

“It’s just an entirely different problem,” he said. “You learn little pieces between each one that contribute to the other, but the biggest carry over is some of our localization algorithms and the way we can see our environment and move around.”

The NASA Sample Return Challenge is broken up into two stages, both of which are hosted by Worcester Polytechnic Institute in Massachusetts. The first stage is the second week of June, and the next round is the first week of September for teams who advance.

Alabama Astrobotics is made up of about 40 students from across engineering disciplines, computer science and other areas of campus, and is advised by Ricks and Renea Randle, mathematics instructor at Shelton State.

As part of a required educational outreach component, members of Alabama Astrobotics have hosted outreach activities on campus during E-Day and game day tailgates. Additionally, the team has worked with students at University Place Elementary School in the Tuscaloosa City School System to introduce science and technology concepts through hands-on activities.

The team received funding from the Alabama Space Grant Consortium, NASA, Dynetics, Fitz-Thors Engineering, the UA College of Engineering, the UA Student Government Association, the UA Graduate School, and Shelton State.

Contact

Adam Jones, engineering public relations, 205/348-6444, acjones12@eng.ua.edu