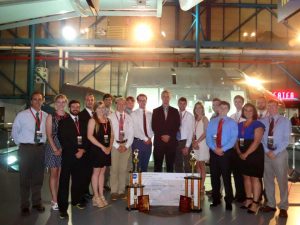

TUSCALOOSA, Ala. — Add another national title to the Crimson Tide trophy case. This past weekend, a team of students from The University of Alabama won a NASA contest against teams from across the country.

Made up of students from The University of Alabama and Shelton State Community College, Alabama Astrobotics earned the most points in NASA’s Robotic Mining Competition, which challenges collegiate engineering and computer-science students to build a robot capable of navigating and excavating simulated Martian soil.

With the overall prize, UA became the only school to win the contest twice during the competition’s six-year history.

Made up of students from across engineering disciplines, computer science and other areas of campus, the team of UA and Shelton State students won the contest in 2012, placed third in 2013 and second last year. The team also finished fourth and sixth place in the first two years of the competition.

“The 2015 NASA RMC National Championship cements Alabama Astrobotics as the top robotic space mining program in the country,” said Dr. Kenneth Ricks, UA associate professor of electrical and computer engineering and team adviser. “This consistent level of excellence is unmatched and stands testament to the hard work and dedication of our students.”

NASA invited 47 university teams to compete in the mining contest during the third week of May at the Kennedy Space Center in Florida. On May 22, the last night of the competition, NASA officials announced Alabama Astrobotics notched the most points in the competition, winning the Joe Kosmo Award for Excellence as the top overall team.

As part of the competition, students are required to design a robot capable of navigating through and excavating 10 kilograms of simulated Martian regolith, a layer of loose material that covers a solid rock.

The robot is allowed two competition runs of 10 minutes each to move across the arena, through an obstacle area, excavate as much regolith as possible, and return the collected regolith back to the starting area.

This year’s competition places additional emphasis on the robot’s ability to gather simulated ice buried beneath the regolith.

The team was judged on a written systems engineering paper; slide presentation and demonstration; project outreach in promoting science, technology, engineering and math disciplines; team spirit; the mining category; autonomous operation; and efficiency in communications.

Besides being the overall winner, the UA team also placed first in the mining category; slide presentation and demonstration, autonomous operation; and efficiency in communications. For the autonomy award, the team received the Caterpillar Award for Full Autonomy.

In all, the team brought home $10,000 in prize money to be used for next year’s team.

This year, the UA team focused primarily on building a lighter, autonomous robot. To accomplish this, the team built a new, smaller robot with a redesigned off-loading method that uses a conveyor belt to gather, store and deposit the regolith.

To make the robot autonomous, the team used Lidar sensors that use lasers to focus on a target and determine the location of the robot relative to that target.

The team’s first competition run was completed by the robot fully autonomously, the first robot in the contest’s history to complete a run with complicated autonomous programming that could be used by an actual NASA robot on another planet or asteroid, Ricks said.

“The 2015 UA robot was among the lightest, fastest and most robust designs ever entered in the competition,” he said. “Combining the mechanical design with the onboard intelligence, overall this robot has no rivals from all those that have competed in the six years of this competition.”

Along with Ricks, Renea Randle, mathematics instructor at Shelton State Community College, served as an adviser for the team.

The team received funding from the Alabama Space Grant Consortium, NASA, Dynetics, Lockheed Martin, Nucor Steel, the UA College of Engineering, the UA Student Government Association, the UA Graduate School and Shelton State.

Contact

Adam Jones, engineering public relations, 205/348-6444, acjones12@eng.ua.edu;

Source

Dr. Kenneth Ricks, 205/348-9777, kricks@eng.ua.edu