By Katy Echols

Photos by Zach Riggins

Engine failure is often unavoidable. Factors such as overheating, weathering and electronic failure weaken the engine. However, there is one detrimental element often overlooked: noise.

For engines to run, combustion is required for the production of energy. During the combustion process, air is compressed within a chamber, increasing pressure. The injection of fuel within this high-temperature, high-pressure environment creates a flame. The flame acts like a microphone, producing a deafening noise as it amplifies the sounds present in the flow.

That noise can also be “deafening” to the engine. Because the noise level is so high, the sound waves produced cause intense pulsations. Those pulsations shake the engine and can cause mechanical failure. The more the engine is exposed to these intense acoustic pulsations, the shorter is its lifetime.

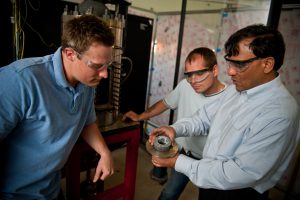

Dr. Ajay Agrawal, the Robert F. Barfield Endowed Chair in Mechanical Engineering at The University of Alabama, is working with the U.S. Navy to address the issue of noise in jet engines. Many of their naval aircrafts showcase the issues of noise and instability during takeoff, affecting those around the aircraft. The goal is to significantly quiet combustion, possibly making work environments safer and extending the life of equipment.

“All our research ties into energy,” Agrawal says. “In the process of generating thermal energy, the surrounding environment is affected. This includes people. We want to improve that impact.”

So far, noise reduction has always been addressed after-the-fact by suppressing the noise outside the engine after the combustion process has occurred. Agrawal is exploring new methods of alleviating these issues that eliminate the noise at the source — during the combustion process.

The challenge of cutting the sound level during combustion is that it happens at extremely high temperatures and pressure. Most material cannot withstand such conditions. However, Agrawal recently developed and received a patent for a breakthrough technology utilizing a sponge-like material to reduce noise at the source.

This sponge-like material is a composite made of hafnium carbide and silicon carbide. It can withstand intense levels of heat and pressure. The material is placed directly into the flame and acts like a sponge for the noise.

With its high permeability, gases can easily flow through so the combustion process is not interrupted, but the noise problem is addressed. The material surrounds the flame, cuts the noise and eliminates the potential for engine instability.

“Experimenting with efficient jet fuel combustion is so noisy and unstable,” Agrawal says. “It shakes the whole building, and you can’t hear anything. But when you put the sponge material in place, you can talk to the person next to you. It’s a night-and-day difference.”

Because this technology reduces noise at its source, it eliminates the need for bulky and expensive modifications to exhaust equipment. It also increases the uniformity of the combustion and allows for retrofitting of existing systems, which is highly cost efficient. This technology will be useful in gas turbines, burners, furnaces, power generators and other industrial devices using combustion.

The application of the technology extends beyond jet engines. Some chemical manufacturers place loud, high-capacity torches at ground level instead of safer heights to control noise. Factories that rely on combustion also face government regulations to protect employees from noise.