TUSCALOOSA, Ala. — Efficient electric machines power much of today’s energy technology and are looked to as crucial to emerging energy industries. Unfortunately, they are powered by a limited global supply of certain naturally-magnetic minerals that grow costlier as demand increases.

A University of Alabama engineering professor hopes to swap these rare earth minerals with more abundant substitutes to drive down costs and encourage swifter adoption.

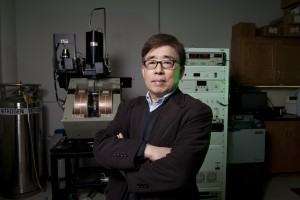

The United States Department of Energy recently awarded Dr. Yang-Ki Hong, the E. A. Larry Drummond Endowed Professor of Electrical and Computer Engineering in the UA College of Engineering, along with a team of researchers, a $1.26 million grant to determine if the idea works by creating a bulk permanent magnet using the substitute minerals and demonstrating it can function as well as, if not better, than current rare earth permanent magnets.

“We want to prove our concept and then manufacture permanent magnets without these rare-earth materials,” Hong said.

Hong is the lead on a team that includes Dr. Tim Haskew, professor and interim head of the electrical and computer engineering department, and Dr. Oleg Mryasov, associate professor of physics, along with researchers from Mississippi State University and the University of California San Diego. The grant began this year and lasts for three years.

Hong’s grant comes from a program called REACT, or Rare Earth Alternatives in Critical Technologies, of the Department of Energy’s Advanced Research Projects Agency Energy. It funded 14 projects nationwide aimed at reducing or eliminating the dependence on rare earth minerals through development of substitutes in the crucial areas of electric vehicle motors and wind generators. The Department of Energy hopes to improve how the U.S. produces and uses energy by accelerating innovations in clean technology.

The use of rare earth minerals as permanent magnets, materials that create their own continuous magnetic field, has caught on in roughly the past 30 years as research has expanded their power and usage. Rare earth permanent magnets are the most powerful and efficient magnets, and their size and reliability suit them well for electric motors that use their magnetic field as power.

Trouble is, though, the increased demand for the limited supply of rare earth has jumped prices as much as 700 percent for some minerals in the past year, according to the Department of Energy. Also, about 95 percent of the world’s supply of rare earth materials is produced in China.

Price instability makes it difficult to rely on rare earth minerals and threatens widespread adoption of many energy solutions by U.S. companies, according to the U.S. Department of Energy. Hong has one U.S. patent pending and has filed for another provisional patent.

He is working with The University of Alabama Office for Technology Transfer to help guide research and development efforts with an emphasis on ensuring commercialization, said Dr. Rick Swatloski, interim director of OTT.

Under Hong’s proposal, the substitute permanent magnet would use the abundant elements of manganese and bismuth surrounded in a film of cobalt iron and nickel iron that would be much cheaper to produce than rare earth magnets. This magnet could also operate at higher temperatures than rare earth magnets, which begin to lose magnetic properties when hotter than roughly 390 degrees Fahrenheit, Hong said.

The grant from the Department of Energy is the first step toward commercialization, he said.

“If we succeed in proof of concept, we will have more chances to do advanced research,” Hong said.

Graduate and undergraduate students working with Hong and Haskew in labs devoted to magnetic materials and devices along with electromechanical systems are learning advance technologies and will be better prepared to work in these fields after graduating, Hong said.

In 1837, The University of Alabama became one of the first five universities in the nation to offer engineering classes. Today, UA’s fully accredited College of Engineering has more than 3,300 students and more than 100 faculty. In the last eight years, students in the College have been named USA Today All-USA College Academic Team members, Goldwater scholars, Hollings scholars and Portz scholars.

Contact

Adam Jones, engineering public relations, 205/348-6444, acjones12@eng.ua.edu

Source

Dr. Yang-Ki Hong, 205/348-7268, ykhong@eng.ua.edu; Dr. Rick Swatloski, 205/348-8583, RPSwatloski@ua.edu