by Janice M. Fink

A research team in The University of Alabama’s College of Engineering is assisting the U.S. Air Force in selecting the best steel alloy to use in its next generation of air-launched weapons.

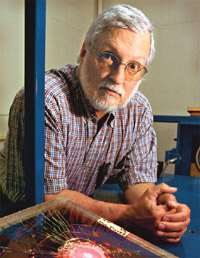

Dr. Stanley Jones, Cudworth Professor of Aerospace Engineering and Mechanics, along with two graduate students and four undergraduates, is conducting ballistics tests for the Air Force involving high-speed penetration, the results of which could be helpful in developing smaller, faster, more versatile air-launched weapons.

Their findings will assist in determining the right kind of steel casings to use in new highspeed weapons technology.

To study the effects of high-speed penetration on various steel alloys, the researchers fire projectiles from a gun tube at one end of a table toward a concrete or metal target at the other. As the bullet-shaped objects travel, they pass through two laser beams, spaced two inches apart, which measure their impact velocity. The firing apparatus produces projectile speeds of 374 to 1,200 meters (1,200 to 4,000 feet) per second, according to Jones.

A container underneath the target collects the powdery debris that is eroded off the nose of the projectile during penetration, and this powder is studied along with the spent projectile. They determine the “deformation profiles” or eroded shapes of the projectiles, which are dependent upon their original shape and the material they are made from.

“These are the most controlled penetration tests of any being done in a lab environment today,” Jones said. As a result of their findings, Jones has even proposed his own projectile nose shape, called “the optimal geometry,” which penetrates farther in a frictionless environment, he said.

Robert Davis, a junior majoring in aerospace engineering and mechanics, develops the computer programs used in the research. Davis is enrolled in UA’s Computer-Based Honors Program, which has been cited by the National Institute of Education as one of the six most intriguing honors programs in the country. A presentation on his programs for modeling the ballistic theories, titled “Analysis of High-Speed Friction,” won him first-place honors in verbal presentation at the first University of Alabama System Honors Research Day, held in April. He was also recently named Outstanding Undergraduate Researcher by the AEM department. Davis said he wants to someday work for NASA to develop advanced propulsion systems.

“Rob’s ability to design such strong computer programs allowed us to have a paper published in the Journal of Mechanical Engineering Science,” Jones said. “I have an excellent team of people working with me,” he added, “but Rob fills a unique niche.”

Jones is also performing a fundamental study on the impact penetration of glass using the same tabletop apparatus, along with Dr. Mark Barkey, associate professor in aerospace engineering and mechanics, and Dr. Richard Bradt, professor and head of metallurgical and materials engineering. The glass experiments use lower velocities and higher diameter projectiles, Jones explained, and the results could assist with the redesign of bullet-proof glass.

Jones, who has over 34 years of experience in his field, joined the UA faculty in 1987. His research and teaching activities cross departmental lines — he also serves as an adjunct professor of metallurgical and materials engineering.